Block plane meets the lathe

After using gouges to take square stock close to its finished form, Mario Rodriguez often relies on a block plane to achieve a smooth taper when turning.

I don’t consider myself a turner, more like a furniture maker who turns when necessary. So after using gouges to take square stock close to its finished form, I often rely on a block plane (used on the spinning workpiece) to remove any bumps and achieve a smooth taper. There’s no danger of ruining the work or damaging your plane. Set the blade for a light cut and press the plane against the spinning workpiece. This technique sometimes leaves very light spirals, but they are easily removed by sanding.

Creating the tenons

I often size round tenons with an open wrench. It gives me a slightly oversize tenon that is easily tweaked for a tight fit. I turned all the parts here to die smoothly, shoulderless, into their mortises. I think it’s a cleaner, more attractive look. Before removing each part from the lathe, I took the opportunity to sand to 220 grit.

Text is excerpted from Mario Rodriguez’s Build a modern coffee table in Fine Woodworking #291.

|

|

|

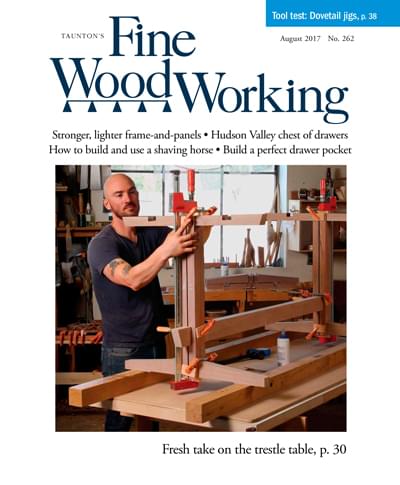

Shop Tour: Mario Rodriguez’s Woodshop Classroom and Curriculum |

|

Scandinavian Kitchen Table |

Comments

I suspect the edge of the plane blade is reaching a much higher temperature in this application as the material removal rate is considerably higher than a normal hand planing use. I would think there's a good chance the blade could lose its temper qualities.

Log in or create an account to post a comment.

Sign up Log in