Geeky woodworking tests

A collection of our best smash-em-up tests aimed at making your joinery stronger.

Whether we are enlisting the help of scientists, period furniture makers, or college professors, we—the editors at Fine Woodworking—recently came to a realization about ourselves. We kind of like breaking things.

We must like it; just take a look at all these different articles where we smash, compress, or otherwise harass perfectly innocent woodworking joints, just to watch them fail. Anyone would think we had a real mean streak to us.

The truth is, though, that the goal is always the same—better results for ourselves and for you. We want the furniture you make to be strong, and the joints you spend so much time crafting to stand the test of time. So sometimes we break out the hydraulics and ask the scientists. Sometimes we get a little destructive. It is kind of fun, and the results can be eye opening!

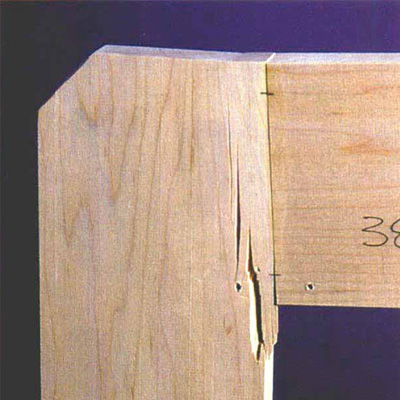

Joinery Shootout

We push 18 popular frame joints to the breaking point

By Douglas Moore, Thomas McKenna #203–Jan/Feb 2009 Issue#203–Jan/Feb 2009 Issue

When designing a piece of furniture, how do you decide on the joinery? Chances are aesthetics, efficiency, and available tools factor into the decision. But so does strength. Fine Woodworking teamed up with a group of research engineers to test 18 popular frame joints and see which is strongest. We made five sets each of 18 different types of joints in cherry, a species used often by furniture makers. The samples were placed in a servo-hydraulic materials testing machine–essentially a hydraulic ram hooked up to a computer to record force and movement–and broken. Which ones were sturdiest? The results will surprise you.

How Strong is Your Glue?

We take six types of glue to the breaking point, shattering some common wisdom in the process

By Mark Schofield #192–July/Aug 2007 Issue

Glue is so essential to woodworking that there are dozens of types and masses of competing brands. There is also a lot of “conventional wisdom.” To see if that conventional wisdom has any basis, Fine Woodworking ran a test on six common types of woodworking glue — a traditional yellow glue (PVA), a Type I waterproof PVA, a liquid hide glue, a hot hide glue, a slow-set epoxy, and a polyurethane.

Tips for Stronger Tenons

By Dan Bollock #259–Jan/Feb 2017 Issue

Wood researcher Dan Bollock broke more than 150 mortise-and-tenon joints of different widths, lengths, and thicknesses to see exactly how size, fit, and glue-up procedures affect the strength of the joint. He found that width plays the biggest role, but that length and thickness also make a huge difference. Not surprisingly, a joint that fits well is stronger. Also, the strongest glue bond was created by applying glue to both the mortise and the tenon.

Get Serious About Clamping

Learn the science behind clamping, for perfect glue-ups

By Roman Rabiej #194–Nov/Dec 2007 Issue

For most woodworkers, the glue-up process is an inexact science. But for wood technologist Roman Rabiej, judging the success and potential longevity of a glue-up is simply a matter of determining the clamping force you need, choosing the correct types of clamp, and placing them where they will do the most good. Rabeij explains the science behind clamping in terms that will ensure that you approach your next glue-up with confidence.

Testing Joints to the Breaking Point

By Bruce Gray #148–Mar/April 2001 Issue

Log in or create an account to post a comment.

Sign up Log in