Running electrics in my dream shop

Every woodworker has different needs, but Vic Tesolin knew that 100-amp service would be enough to power his dream shop.

Just like building any woodworking project, setting up a shop requires a certain Order of Operations. Now, unless you are working by candlelight, there is likely the need for electricity in any shop. All of my “apprentices” need electricity, which is probably cheaper than room and board, so I wanted to make sure there was plenty. Every woodworker’s needs will be different, so take this with a grain of salt. This is my dream shop so I’m putting a lot into it.

The home my spouse and I bought has 200-amp service, so that was a good start! The house also uses natural gas for the dryer and range, which means the two biggest draws on a home’s electrical panel are gone. This made the decision to bring 100 amps into the shop easy. Now, there is a lot that I’m willing to tackle as a DIYer, but electrics is not one of them. Knowing that I’m able to hurt myself changing a light bulb sometimes, I left this to the pros. The electricians ran 150 ft. of one aught (1/0 AWG) cable back to the shop building, laid into a 2-ft.-deep trench. I felt bad watching the young lads tugging that huge cable to the shop, but only for a second.

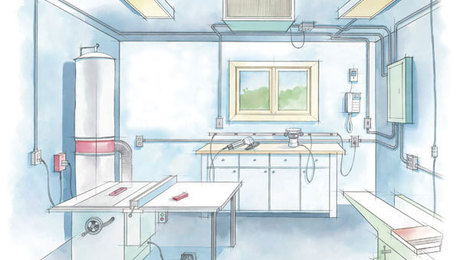

Once the 100-amp panel was in, the electricians started installing the 110-volt and 220-volt outlets, running the conduit, and pulling wire. I located all of the receptacles based on my best guess according to the floor plan I toiled over for a month or so. This was by no means the final layout, but I felt it was a good start. Essentially there are 110-volt receptacles along two walls of the shop for the tools that live on those walls. Then there is a board mounted to the ceiling with both 110-volt and 220-volt receptacles to supply the machines clustered in the center.

If my plan for the tool cluster pans out, then I may install a 4×4 post, floor to ceiling, to run the power down on. This will reduce the chances of plugs coming out of the receptacles over time. The true test will come when I mill up some material using the jointer/thicknesser and bandsaw to make parts. So far, the flow looks good but only time and experience will tell.

The final loads on the power are a split heating/cooling unit and a dehumidifier that will keep the shop comfortable. With a background of 14 years in the combat arms of the Canadian military, I have a good sense of what it feels like to work in uncomfortable conditions. While I’m proud of that time and my service, I admit that I like to be more comfortable when I can. The seasons can swing dramatically where I live, going from as cold as -30°C in the winter to as warm as 40°C in the summer*. Not to mention the 50-60% swings in relative humidity, so I wanted to be comfortable. While the trench was open, I also ran network cable so that the internet connection in the shop was primo.

With the electrical finished and the walls patched and painted, it’s time to unpack boxes and find places for everything to live. It’s been a month of non-wood working and I’m ready to start making shavings again.

*Southern translation: -22ºF in the winter to as warm as 104ºF in the summer.

|

|

|

|

|

Comments

Hi Vic. I am also building a shop in my yard. I never thought to pull a cable when the power line is dug to get good internet out there. Thanks for the tip. I will be breaking ground in a month. Where can I get more about your new shop including the decisions you made for construction and work flow.

One suggestion Vic. MOVE, -30 to +40, there are way too places around Canada with much nicer weather that.

Vic,

Installing a 100A sub-panel is a wise choice where trenching is needed. The wiring material cost is incidental to the excavating. I always recommend PVC (inexpensive) conduit and an additional empty conduit to future-proof the installation. In most cases a 60A panel is sufficient if pipe and wire costs become a challenge. Deciding where to place receptacles and which flavor is tough even when you have a decent idea of machine and bench placement. In both my St. Paul and Grand Marias shops I installed wire mold which allows not only unrestricted placement of receptacles, but more importantly the ability to easily add or re-arrange devices. I was not in my new shop two months before adding and moving receptacles. Also good plan installing outlets in the ceiling. If you use twist-lock devices for your 220v equipment and buy premium quality 120v overhead connections you will not have any trouble with pull-out. For convenience I dropped SO cord pigtails with, again quality such as Hubbell, connector about 6 feet off the deck for easy access. When new construction allows a floor monument for receptacles eliminates the inconvenience of vertical obstructions.

I just did a live virtual tour of my shop that you can watch here.

https://www.youtube.com/watch?v=_xmOzyC0gsA

LOL. I'm good with the weather. I can have fun in the sun of the snow.

Thanks for your thoughts! I like the wire mold idea.

Log in or create an account to post a comment.

Sign up Log in