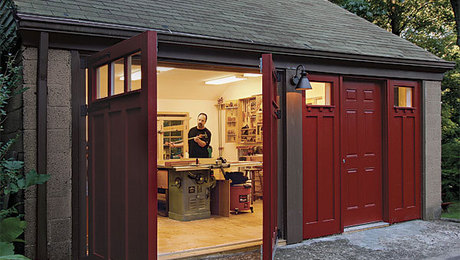

Shop Tour: Ben Strano’s dream shop

Ben Strano shows off his 340-sq.-ft standalone shop and explains why he made the choices he did when setting it up.

We’ve been in our house for a little over four years now. My shop has been in a workable state for about a year and a half. In that brief time, I think I’ve changed the layout of all of my tools at least three times, the latest of which was about six weeks ago. Based on my current work and tooling, I think I’ve stumbled upon what I consider my ideal working setup.

The building

My shop is a stand-alone building that at one point might have been able to house three very small cars, or possibly farm equipment. Given that the house dates back to the 18th century, anything is possible. I don’t have the evidence to prove my theory, but looking at the framing, I’m pretty sure this building has been rebuilt multiple times–each time adding height or width. I didn’t want my lawn tractor, snowblower, camping equipment, bicycles, and random junk storage encroaching on my shop, so I walled off one bay to dedicate as a garage area. Yes, I lost a third of the possible working area, but those aforementioned items aren’t in my shop, bothering me and waiting to be tripped over.

Let’s flip this card over and check out the stats!

Ben Strano’s shop:

Dimensions: 270 sq. ft. of working space (18×15) plus 72 sq. ft. of storage area

Year built: ?

Year turned into a woodshop: Early 2019

Power: 100-amp service

Insulation: Yes, as much as I could afford

HVAC: Wall unit AC and space heaters. More heat coming soon… I hope.

Sound system: (2) JBL4328 powered studio monitors… ’cause I don’t mess around.

Overview

I had two main goals when setting up my shop.

1) I wanted an efficient place to work. I don’t like moving tools around. I like to leave things set up and ready to go as much as possible so I needed a layout that allowed me to easily use the tools I use the most.

2) I wanted to be inspired when I walked in into my shop, and I wanted it to be a pleasant place to spend many hours. I also wanted my shop to reflect my personality and aesthetic. While it’s constantly evolving and being added to, I am pleased with the bones. It took a lot more time and money to put up shiplap pine and painted plywood, but it was worth it to me and my family.

Bench Area

I have two workbenches, neither of which is anything to write home about. I have a small and flimsy bench that pulls double duty as both a workbench and an outfeed table for my tablesaw, and a bench built into the wall under my window. This second bench is much higher than most, making it a better height for carving—which I am likely to spend hours doing as opposed to planing, which is minutes.

I don’t have a tool chest or cabinet. All of my hand tools are out, ready to use. I try and be minimalist about my tools. Yes, I enjoy collecting and using nice tools, but if I find myself with a tool I never use, it will be sold or donated quickly.

Machine “Cluster”

Like I said earlier, I like to have my tools out and ready to use. Of all of my machines, the only one that gets put away is my planer. Some of my machinery might be familiar to readers. My Delta Unisaw and lathe used to reside in Mike Pekovich’s shop and the Powermatic PM60 is from the old FWW shop. Unfortunately I don’t have solid dust collection yet and it’s proven to be the true weakness of my setup. Since my Grizzly 14-in. bandsaw is by far my most used machine, I have a small dust collector attached to it on an automatic switch. I need to figure out some dust collection for my tablesaw. While I don’t use it very often, when I do I am immediately reminded how much fine dust it can throw into the air.

“High Tech” Area

Tucked away in the storage area of the shop–where the ceiling is too low to walk– is my duo of robot underlords, a small Shapeoko 2 CNC machine and a Creality Ender 3 Pro 3d printer. My lightbulb kiln is tucked away in the corner across from my general tool storage–screwdrivers, socket set and lots of pliers which I still haven’t found a satisfactory way of keeping at the ready.

Storage

This area would be familiar to anyone who watched my video, Organize your hardware, organize your shop. This section of my shop still makes me smile every time I go over to it. Having everything organized and in order is just a joy for me. Just last night, I needed to find my stash of glue syringes. I hadn’t used them in over a year and didn’t remember where they were. I stopped for a moment and said to myself “where would you put them right now?” There they were in the “Glue up stuff” drawer. The little things like that make this shop a joy to work in, even now that all of us at Fine Woodworking are working remotely and I’m in here on a computer from 9-5.

|

Turn Your Garage Into a Real WorkshopMichael Pekovich set out to turn a dark, damp, cold garage into a warm, four-season workspace. |

|

|

|

Comments

Nicely done shop tour. May all of our shops and workspaces bring us equal joy.

I really enjoyed reading about your shop, Ben. Mine is a similar size and I’m impressed in how much you got into your shop without it looking crazy crowded.

Looks great and enjoy the hell out of it!

Great workshop and likewise for the video Ben. You've done a fantastic job with the space and don't be so apologetic about aspects of it (imagine that coming from a Canadian, eh?). It truly is a great space and most importantly, it is your space. Thanks for inviting us in.

Cheers,

John

It is so enjoyable to watch a person that appreciates his shop, a place to go and unwind. Love the color teal walls, the use of shiplap for a wall surface and a great window to view all types of weather. Many great storage ideas and a fine wood shop to work in.

Thanks,

Gale

Loved the video. How do you heat the shop? My shop is of a similar scale and layout. It is well insulated other than the garage doors. I currently use a kerosene heater which doesn’t work very well and stinks. Thanks

Just read the narrative and see you are using space heaters and hoping for more heat. What type would be your preference?

If I had the money I would install a mini-split. Everyone I know who has one loves them.

I love snooping through other people's shops for layout tips and storage solutions and just to ruminate over their tool selections. My main takeaways from Ben's shop- Wera screwdrivers and Marshmallow Fluff containers. :)

Very nice video, Ben, thanks for doing it. One bit of inspiration I'm taking from it is that I'm going out and attaching my provisional (ahem) workbench to the wall (of the garage).

Are those your chickens?

By far, the most enjoyable shop tour. It makes me rethink my shop, "what could I do different?" Thanks Ben

Log in or create an account to post a comment.

Sign up Log in