Chair Repair: When a Dowel Joint Breaks

Broken dowel joints are common when restoring old chairs. David Johnson demonstrates his techniques for bringing life back to these classics.

This Moller chair has a break in the dowel joint where the side rail meets the back leg. Repairing failed dowel joints follows a similar sequence to repairing a mortise-and-tenon gone bad. To save time, I do much of it by eye, working slowly and carefully. I like to have some undersize dowels to test the fit as I go to make sure everything is lining up.

Drill out the center on the broken dowel with an undersize bit and gradually move up in bit sizes to remove as much of the dowel as possible. Check as you go to make sure you are drilling straight down the dowel and not damaging the mortise.

If you’re lucky, you’ll be able to break the remainder of the dowel from the mortise wall by pushing it in.

If luck isn’t with you, use a narrow chisel to remove the dowel by paring it down to the mortise wall.

It’s easier to get the dowel out of the leg than out of the rail because glues don’t adhere well to the end grain on the leg. Removing the dowel from the rail will be a challenge, but follow the same process.

Next clean out the old glue by drilling it out of the mortise. Take care to keep the bit straight and use only a bit that is 1/64 in. larger than the last. As I do this, I work on both the leg and rail at the same time so I can check my work as I go, putting the pieces together with undersize dowels. It’s very easy to mess up here, so move slowly! On smaller dowels, I like to use my hand drill to better feel the feedback from the bit. Unfortunately, large bits don’t fit my egg-beater-style drill.

To minimize how much larger you have to drill out the mortise, only enlarge it to match the size dowel you can make in your dowel plate.

To ensure accurate sizing, roundness, and availability, I make my dowels with a dowel plate. Chamfer the ends and glue up.

-David Johnson specializes in the conservation of Danish Modern chairs with woven seats from his home shop in Los Angeles. He also produces original work and teaches weaving. You can find him on Instagram (@sidecar_furniture) and on his website, sidecarfurniture.com .

|

|

|

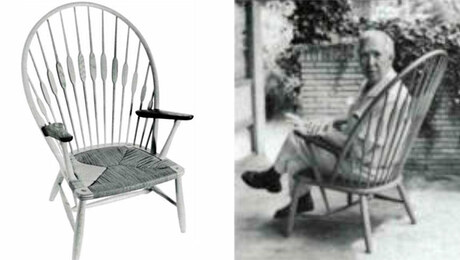

Hans Wegner, Master Chairmaker |

|

Comments

The author notes:

"On smaller dowels, I like to use my hand drill to better feel the feedback from the bit. Unfortunately, large bits don’t fit my egg-beater-style drill".

Having mended a few of the mass-produced furniture chairs in which dowels were used, I know only too well how easy it is to "mess-up" when using a power drill. I would never do so again for re-dowelling.

Perhaps the author might also avoid the risks of the power drill he realises so well by obtaining another hand drill that does take bigger bits? After all, this is an opportunity to buy another tool! :-)

Lataxe

PS dowelled chairs - they should be illegal! The worst possible joint type for a chair (unless you're the manufacturer cutting costs and enjoying the increased selling opportunities of planned obsolescence).

You are correct that the power drill is a faster way to make mistakes as opposed to doing it by hand. My power drill has a setting for its speed and combined with a light touch on the trigger I can run it quite slowly. That should have been in the original text.

As far as acquiring more tools, like all

of us I have an ever growing wish list. Thanks to this I may have to add a larger hand drill to it. Or maybe a brace? An antique one would be cool! See what you started?

While I’m not a proponent of dowelled chairs I am surprised at how long a well dowelled chair will last. In my experience the draw bored tenon is by far the strongest and longest lasting. Even if the glue joint fails the joint will stay somewhat tight keeping the chair together.

David Johnson

Log in or create an account to post a comment.

Sign up Log in