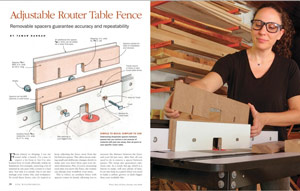

Build an adjustable router-table fence

Get safe, clean cuts on your router table with this shopmade auxiliary fence with removable spacers.

Synopsis: Get safe, clean cuts on your router table with this shopmade auxiliary fence with removable spacers. The spacer system allows you to set the distance between fence and bit just once, while you make a series of incremental passes with the router, removing spacers one by one until you’ve reached your final dimension.

From joinery to shaping, I use my router table a bunch. I’ve come to expect a lot from it, but I’ve also learned how to work efficiently within its limitations. For example, removing a lot of material in one pass with a router is a bad idea. Not only is it unsafe, but it can also damage your router, bits, and workpiece. To avoid these heavy cuts, it’s typical to keep adjusting the fence away from the bit between passes. This often means making small and deliberate changes slowly to make sure you don’t blow past your desired dimension. Plus, if you’re measuring each time you move the fence, the routine can disrupt your workflow even more.

This is where an auxiliary fence with spacers comes in handy, allowing you to measure the distance between the fence and your bit just once. After that, all you need to do is remove a spacer between passes. The setup also guarantees safe, clean cuts. As a result, this jig, which is a breeze to make, will save plenty of time. It can also help in a pinch when you need to make a rabbet, groove, or dado bigger than your available bits.

A breeze to build

The jig comprises a few simple elements. First, there’s the auxiliary fence. This is what the stock rides against, so I make it from melamine. Second are the spacers. You don’t want these thicker than half the diameter of the bit’s shank. I typically use 1⁄2-in.-shank bits, so 1⁄4-in.-thick MDF works great. Having some 1⁄8-in. spacers is nice for smaller bits, as well as for overall versatility. I also like to resaw extra-thin spacers, about 1⁄32 in. thick or so, for when I want to use lighter cuts for a superior finish.

Finally, there are the T-bolts and knobs, which secure the auxiliary fence and spacers to the main fence. These should be long enough to extend through both fences and the spacers while still having enough length left over for the knobs to engage the threads.

The auxiliary fence and spacers should be built to fit your particular router table. When sizing the auxiliary fence, simply rip the melamine to the height of your main fence. The length of the auxiliary fence involves a little more thought. I mount it (and the spacers) using only two T-bolts, one on either side of the cutter, and I don’t want it so long that it will bow if it is not supported by more bolts. So, to determinethe length, I open the main fence all the. way and line up the melamine so that it extends past the bolts by about 31⁄2 in. on either side. Then I cut it to that length.

Rip the spacers to the same width as the auxiliary fence, but crosscut them slightly longer. This will make them easier to install and remove when you use the jig.

Next, locate the holes for the T-bolts. Measure the center-to-center dimension between the two bolts on the main fence and transfer that to the auxiliary fence and the spacers. Since the spacers are longer than the auxiliary fence, mark your pieces based on a centerline. For example, if the bolts are 10 in. apart center-to-center, make your marks 5 in. on either side of the centerline. Also use the main fence to determine the height of these holes on the auxiliary fence. The T-bolts’ heads need to be recessed in the auxiliary fence so they don’t interfere with feeding the stock. So, before I drill for the T-bolts, I plunge-cut short, shallow grooves on the router table to fit the heads. After that, drill through-holes for the bolts.

You can take a few steps to make the spacers easy to add to and remove from the auxiliary fence. First, drill the bolt hole about 1⁄2 in. lower, which will leave a slight gap underneath the spacers when they’re installed. This gap will make them easier to lift up and remove. Second, for a bit of wiggle room, the spacers’ hole should be larger than the diameter of the T-bolt. After drilling these holes, remove the waste below them at the bandsaw, creating a slot that will slide over the T-bolts.

Now that the auxiliary fence and spacers can be attached, you need to make room for the router bit. You will most likely be using this jig with large router bits, so use your biggest ones to lay out this opening in the auxiliary fence and spacers. To easily cut out the opening, drill out the corners at the drill press, then clear out the waste at the bandsaw.

As a last step, I put a very slight roundover on the opening’s outfeed side to prevent workpieces from getting caught on it.

From Fine Woodworking #291

To view the entire article and learn more about Tamar Hannah uses her adjustable router fence, please click the View PDF button below.

Comments

I’ve been watching your videos for a while now and remember this one. It is awesome to see you appear in fine woodworking also!

I'm suspect of changes in humidity that can cause the spacers to shrink/swell and thus throw off the accuracy of the cut. Also, how do you handle 1/32" MDF without it falling apart?

Outstanding idea, though, in spite of the above possible problems!

Log in or create an account to post a comment.

Sign up Log in