You can never have too much light

The head lamp was a bust, but Vic Tesolin's other shop lighting seems to do its job quite well.

Well, I guess that is not completely true. You can have too much light, but in the wood shop, sufficient light is not the norm. Having enough light is critical to success because it allows you to see what you’re doing. I mean really see what you are doing. As I’m in my late 40s, my high-powered reading glasses and good light are a must, so here is what I consider to be good light.

First and foremost, you need to have what I call shin-protector light. This is the general lighting in your workshop that illuminates the space so that you don’t walk into things like saw benches or tablesaw fence handles. I have eight ceiling fixtures that have (2) 13W LED bulbs which are the modern equivalent to the old 100W incandescent, just without all the heat and meter-spinning power consumption.

I could probably get even more light out of 4’ LED tube fixtures, but I don’t feel I need it. These ceiling lights are intended to illuminate the space but not to work by. I’m fortunate to have a bank of windows on one wall of my shop which pumps in daylight (between 5000-7000k depending on the day), so when it came to work lights, I went with daylight bulbs to keep them in the same ballpark.

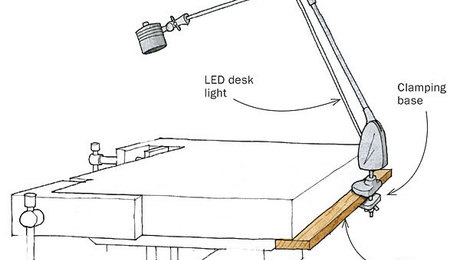

The real heroes in my shop are the $14(CDN) articulating lamps from IKEA. They are inexpensive and not bad quality considering the price. Years ago, I tried to find a great quality articulating light, but they don’t seem to make one anymore unless you want to spend over $100 each. I’m happy with the IKEA ones and as they break over the years, I salvage the parts and keep them in a bin to be used to repair other lights.

I have one of these inexpensive, articulating lights near every tool and workspace possible. These are the lights that allow me to illuminate a specific area and see things clearly as I’m working. They are easily positioned to take away any shadows or can be used at a low angle to provide raking light to check the quality of a surface. You’d be surprised how easy it is to see fine knife markings or light pencil marks by simply placing light right where you need it.

Over the years I have also been experimenting with a headlamp that you would normally use for outdoor adventures. In theory they should be perfect because they are always pointing where the user is looking, but as with many theories, they don’t always work in the real world. The trouble I find is that the light from these headlamps almost always reflects directly back at me, making all the details I want to see washed out. Not to mention the frying of your rods and cones if you do it for too long.

Despite the headlamp being a bit of a bust, I find that I’m in good shape with the room lights on and a dedicated task light pointing at the work I’m doing. Now if I could only remember where I put my readers…

|

STL241: Dust collectors vs. dust extractors |

|

Seeing Better in the Shop |

|

Flexible task lighting for the workbenchJANUARY 28, 2015 |

Comments

Would love to hear what made the head lamp a bust for Vic. I have decent general lighting in the shop but for precision work, I need more light. Was planning to go the head lamp route.

Log in or create an account to post a comment.

Sign up Log in